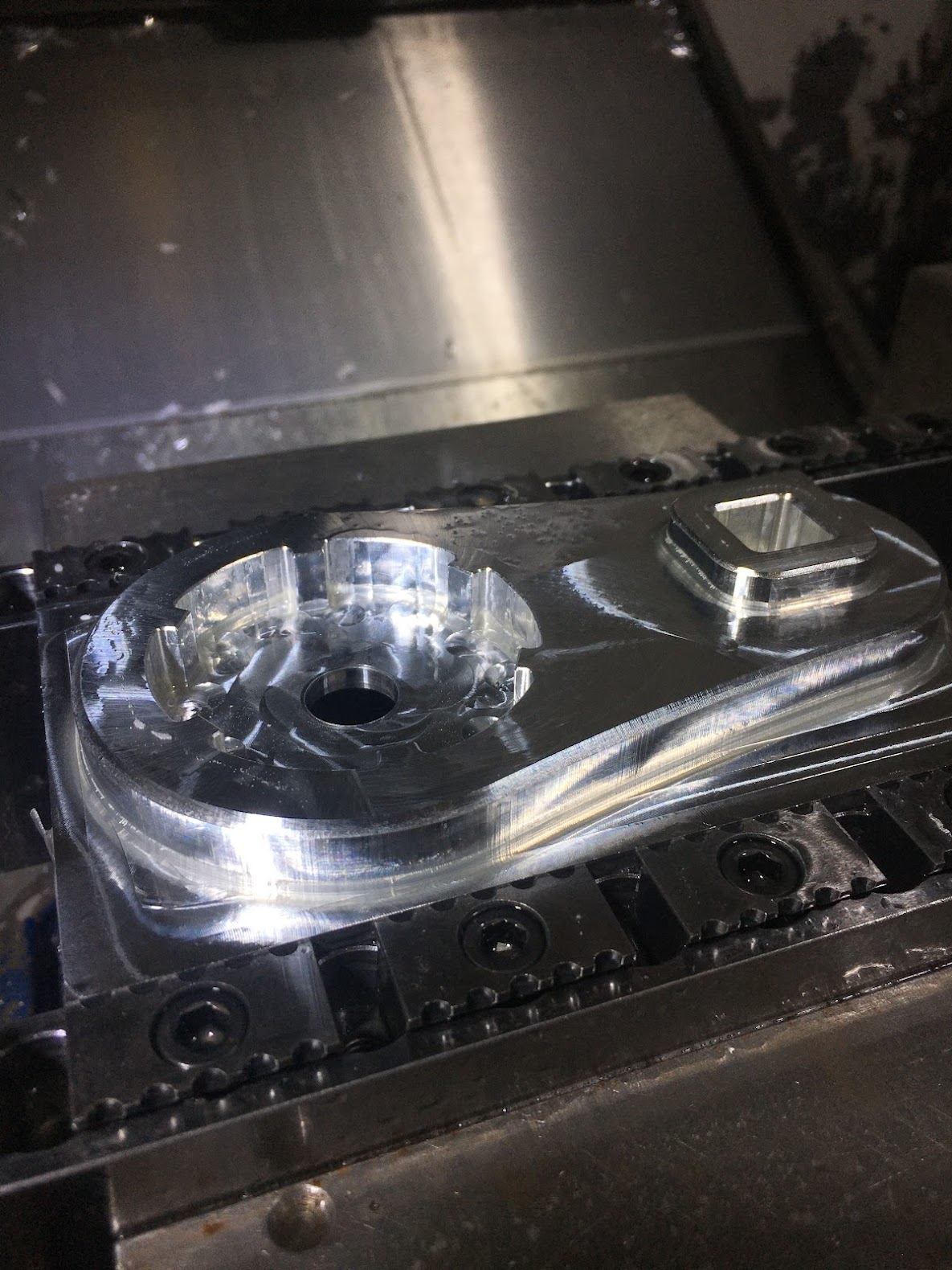

We specialize in iterative engineering design for product development. We work with ideas using CAD/CAM and FEA simulation software to ensure they’re robust and easily manufacturable, and then create the prototypes in-house.

Prototype Development

Design for Manufacture

As a machine shop, we have an in-depth understanding of the manufacturing process. We have experience in taking products through to full production, so our prototype design work is always done with scalability in mind. We can complete small production runs in-house as well, saving cost in early product phases.

Engineering Analysis

We’re not just a machine shop, we’re also degreed engineers with experience in mechanical and consumer product design, including strength analysis and testing of life-safety components. We can work with you to analyze designs, reducing unnecessary iterations and testing expenses.

3D Printing

For quick and cost-effective physical prototyping of new ideas, we offer 3D printing. Between our FDM printer (9" x 8" x 8" print volume) and SLA printer (5" x 3" x 6.5" print volume), we can create parts in a variety of filaments and resins.

Welding

We are equipped for MIG, TIG, and stick welding, which can handle most standard metals, also have plasma cutting capabilities. We primarily focus on small weldments, modifications, and custom parts and fixtures for machine design, and can recommend other local shops for more extensive welding projects.

Previous Projects

Here are photos from a few previous projects we’ve worked on (hover for description and click to enlarge):

Feryok & Clarkson

Feryok & Clarkson