We mill and turn raw materials into precise finished parts. We have the capability and experience to work with a variety of materials including aluminum, steel, stainless, and engineering plastics.

CNC and Manufacturing

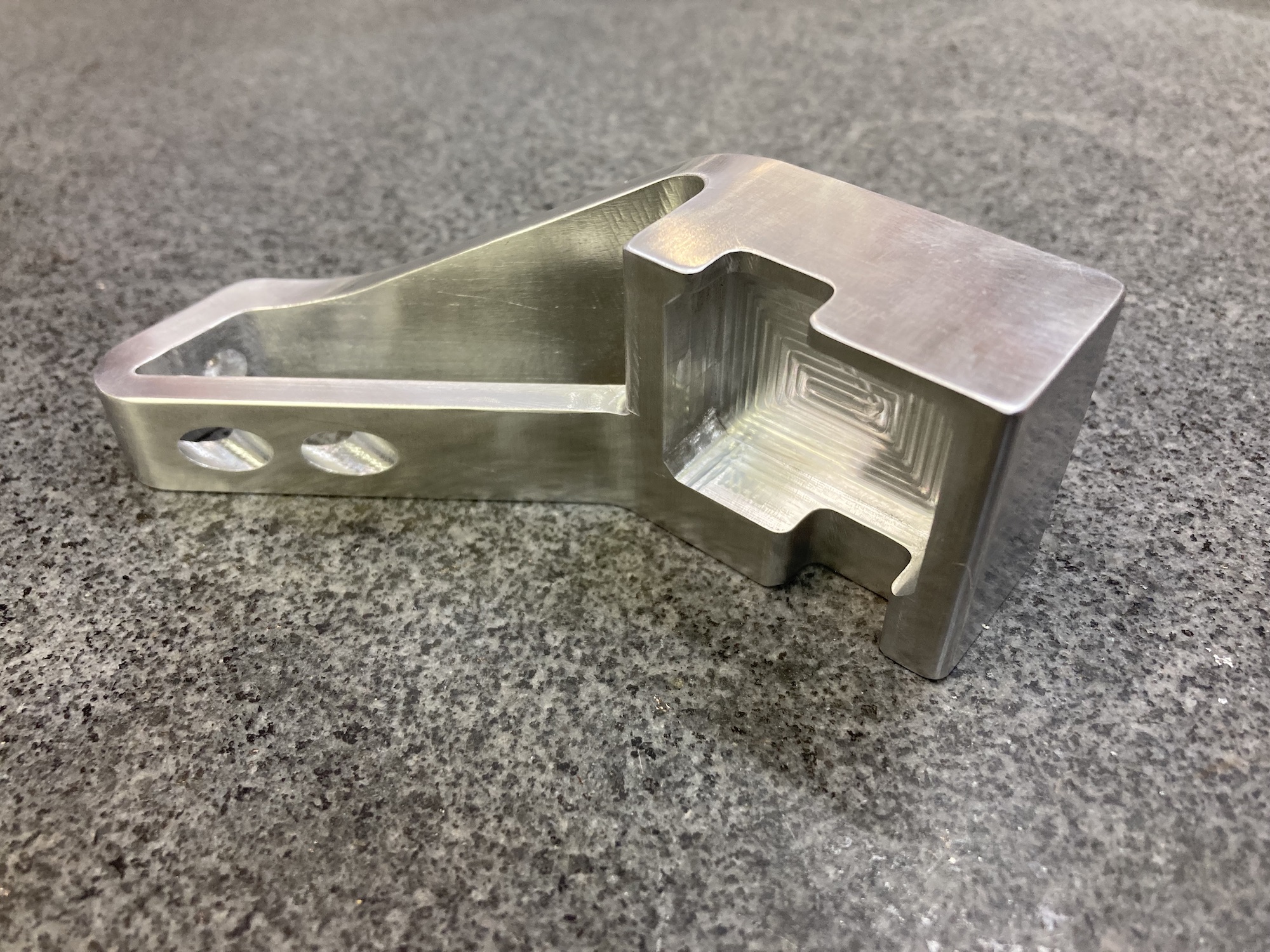

Milling

Haas VF-2SS

With a 12K RPM spindle, rigid tapping, and a 2-axis trunnion for positional 5-axis machining, this machine allows for quick and effective prototyping of complex parts with features on several sides, as well as efficient production for larger runs of parts.

Fadal VMC20

This workhorse is ready to crank out 3-axis parts in large quantities, and can be dedicated for ongoing production on large jobs at an affordable rate.

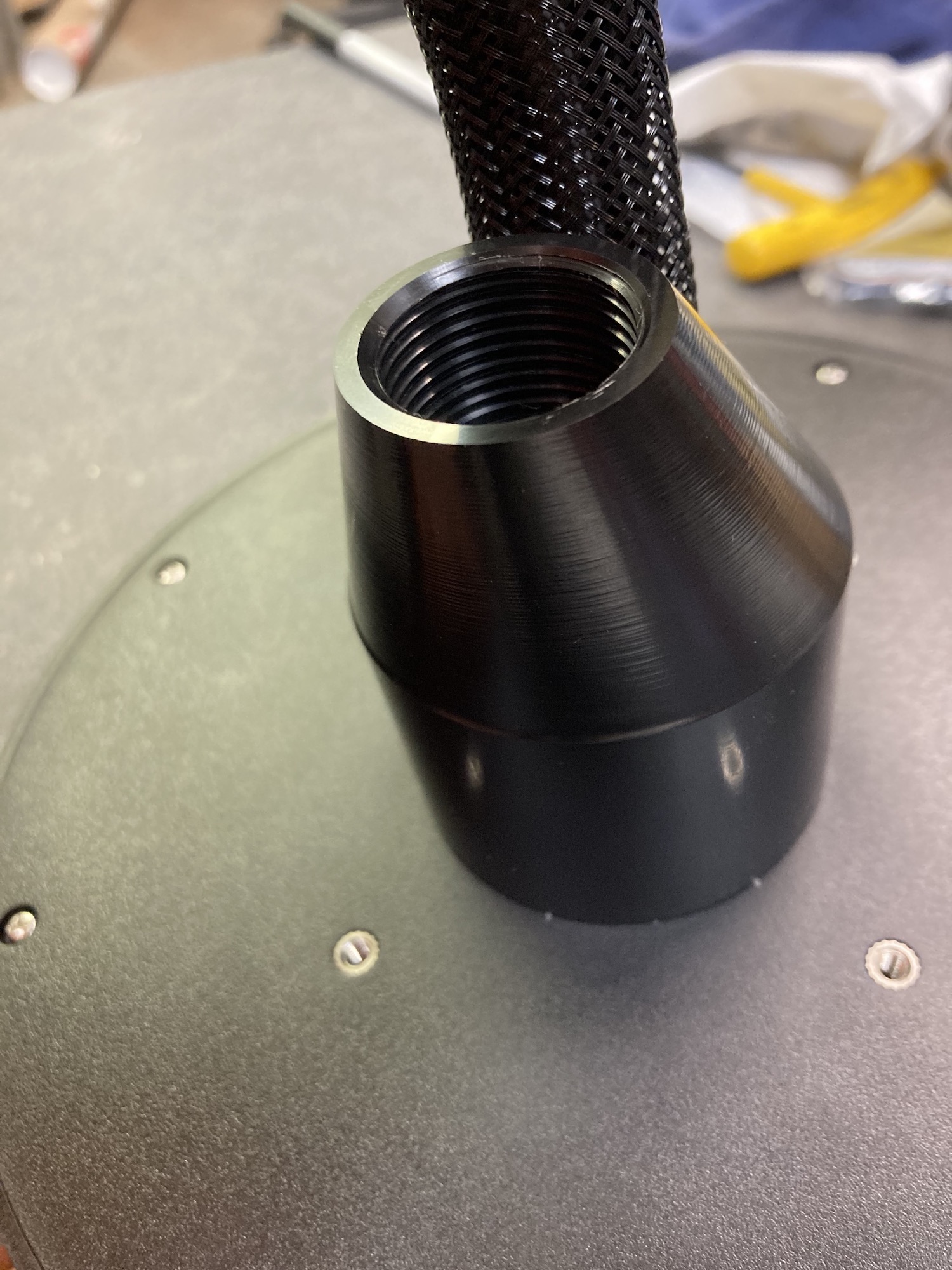

Turning

Mori Seiki AL-2

Our CNC lathe can turn up to 7" diameter and 19" long parts, though material smaller than 1.75" allows us to feed material faster for more cost-efficient production of larger runs. It turns out accurate parts in everything from brass and engineering plastics to hard stainless.

Waterjet

We have a small prototype waterjet for parts up to 12" square and 1" thick and can offer turnaround as quick as same-day for stocked or customer-provided materials. This process can produce intricate geometry which might be difficult or impossible with milling, and doesn’t result any heat-affected zone which can affect material properties along the cut edge. It can also cut composites, glass, stone, some ceramics, and other materials which can’t be plasma or laser cut.

Laser Marking

We have a 30W MOPA fiber laser engraver, allowing effective marking of most metals, including raw or anodized aluminum, as well as a variety of colors on stainless and titanium. This allows us to easily add logos and product information to parts, as well as serialize runs of parts.

Manual Machining

For one-off operations, we have a Bridgeport toolroom mill and a Jet engine lathe, which enable quick repairs, modifications, and production of simple or non-critical tolerance parts without the overhead of a CNC setup.

Previous Projects

Here are photos from some projects we’ve worked on (hover for description and click to enlarge):

Feryok & Clarkson

Feryok & Clarkson